R&D

KORENS Research Center

The KORENS Research Center systematically secures source technology and carries out customer-oriented R&D activities to discover the drivers for new product development and KORENS’ future growth.

KOREN

MISSION

New Product Development

- Development and commercialization of new products which reflect customer needs

- Sharing new business information with subsidiaries within the group/Items to create synergy

- Discovery of future convergence-type items

Securing Core Technology

- Securing infrastructure in the area of environmental friendliness

- Recruitment of specialist researchers

- Participation in cooperative/national policy tasks

R&D Control

- Collection of R&D strategies, division of resources and R&D network construction

- Adjustment of R&D tasks in business areas and suggestions for direction

Current Status of New Technology Development

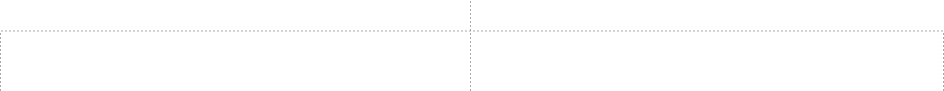

Exhaust Heat Reclamation System (EHRS)

This system aims to capture heat energy which is wasted instead of being converted into power for the automobile and reclaim it in order to maximize energy efficiency.It uses the Rankine steam cycle, a representative system technology, to reclaim heat from exhaust gases and rotate a turbine using working fluid in a high-temperature, high-pressure state to produce mechanical energy. As a steam power cycle, the Rankine steam cycle uses heat sources to turn working fluid into superheated steam which rotates a turbine and allows the device to produce energy.

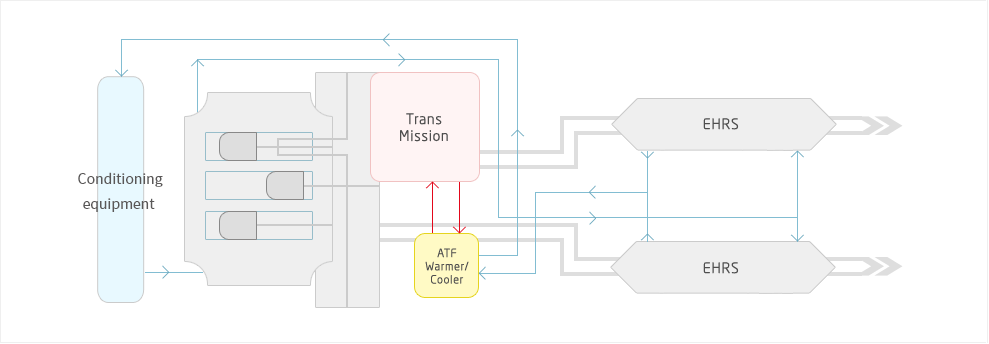

Directly Installed or Attached Water-Cooled ATF Warmer

This component was created by developing conventional air-cooled or radiator self-contained water-cooled A/T coolers into a directly installed exterior water-cooled cooler, and turning the component into a module has effects such as decreased components and wastewater, reduced component size, and simplification of oil and cooling water lines. In particular, the ATF’s fast warmup contributes to increased fuel efficiency and decreased CO2 emissions, making it an environmentally friendly automobile component.

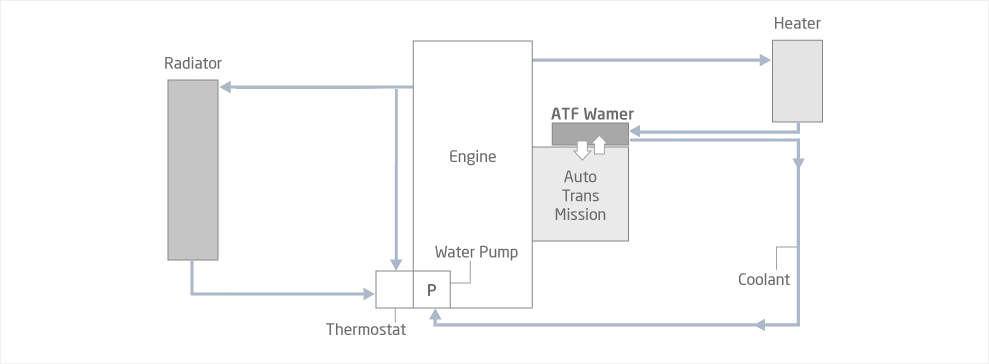

Fuel Cell Intermediary Cooler

Hydrogen fuel cell automobiles use hydrogen electrolysis inside fuel cells to produce electrical energy which is used to power the vehicle.The structure of fuel cells uses electrolytes which can transmit electricity between the cells, with a positive pole and negative pole located in a sandwich configuration. When high-temperature heat is produced, which is one of the chemical reactions which occur inside the fuel cells, a heat exchanger is used to maintain the appropriate temperature.

Battery Thermal management System

With the arrival of the electric vehicle era, the importance of battery thermal management systems for creating energy-efficient transportation is becoming increasingly prominent.A battery must always be maintained at a certain temperature to ensure maximum efficiency and satisfactory durability, which allows a vehicle to have satisfactorily efficient and affordable. When the vehicle is first started, a battery thermal management system uses exterior heat sources to heat the battery, and during driving the cooling system is used to keep the battery at a particular temperature.

KORENS is developing a plate type heat exchanger for transmitting heat within a battery pack in order to maintain temperature, and developing highly efficient, compact heat exchangers using the Fin method, a system for exchanging heat with the outside.